As of October 1, 2024, Dapra Marking is now DM Solutions.

Same ownership, renowned products, and trusted staff — with a few exciting additions. New markets. New products. New services.

Vibro or vibro peen part marking is typically created by a pneumatically actuated machine or device. Unlike dot peen – where the dot placement is controlled – with vibro or vibropeen marking, the dots are positioned based on velocity of the X/Y movement and oscillation of the stylus. Most vibro peen marks are contiguous line characters. Vibropeen marks can also be created on dot peen machines by creating contiguous dots that form a solid line and programming the interdot spacing.

Some specifications may refer to this method as Vibration Peen Mechanical or Vibro Peen Controlled.

Pneumatically powered, high-speed vibro peen marking solution for easy integration into automated production lines.

Compact pneumatically powered, high-frequency benchtop vibro marking solution for deeper marks and marking uneven surfaces.

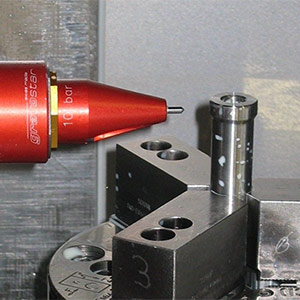

Pneumatic or coolant-driven tools for vibro part marking directly within a CNC machining center, lathe, etc.